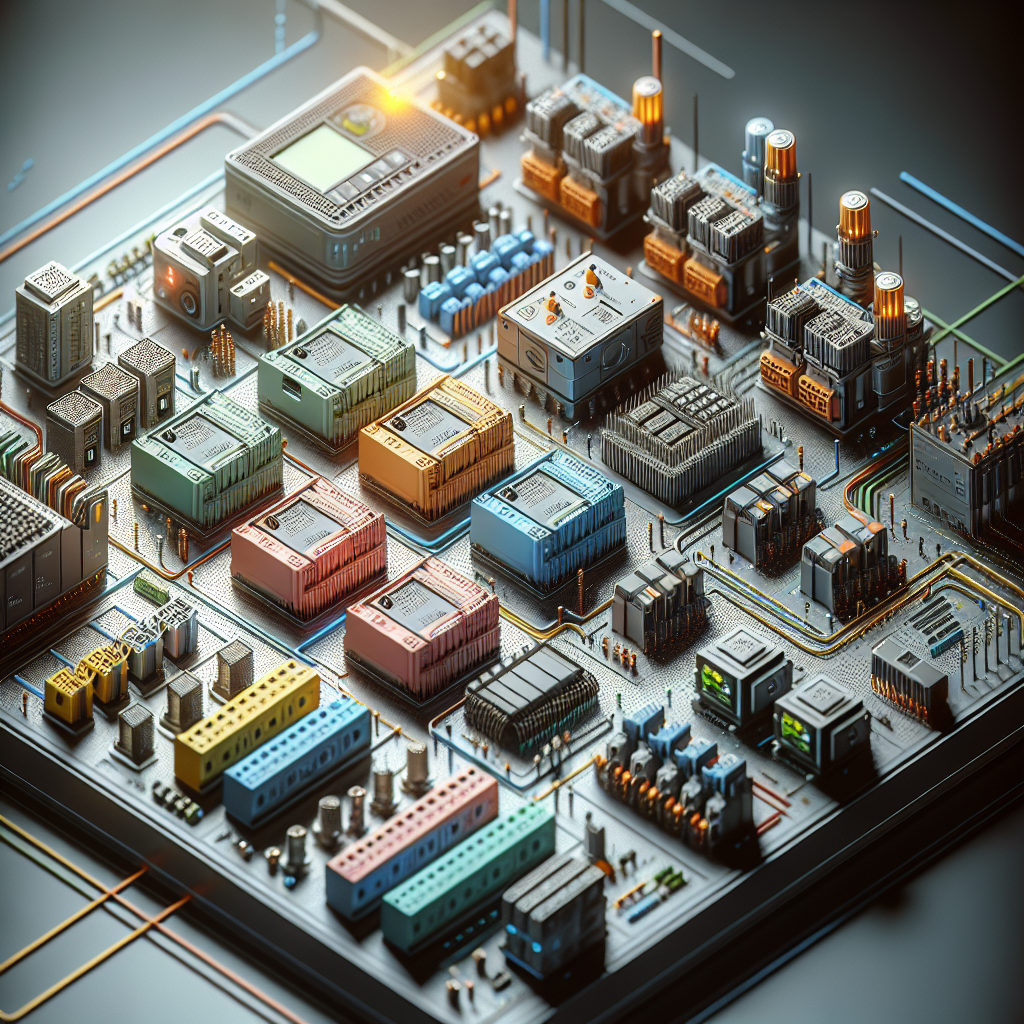

In the realm of industrial automation, analog and digital input output modules play a crucial role in ensuring seamless operations and efficient control systems. For professionals in the industry, having a comprehensive understanding of these modules is essential to optimize processes and drive productivity. Let's delve into the fundamentals of analog and digital input output modules and explore their significance in industrial automation.

What Are Analog & Digital Input Output Modules?

Input-output modules , commonly known as I/O modules , serve as the connecting link between the field devices and the control system in industrial settings. These modules are designed to receive and send signals to and from various sensors, actuators, and other devices in the production environment.

Analog Input Output Modules

Analog input output modules are responsible for processing continuous signals that vary within a specific range. These signals are represented by voltage or current levels, providing precise data from sensors like temperature, pressure, or flow meters. By converting these analog signals into digital data, these modules facilitate real-time monitoring and control of critical parameters in industrial processes.

Digital Input Output Modules

Contrary to analog modules, digital input output modules deal with discrete signals that are either in an ON or OFF state. These modules manage binary data received from devices like limit switches, push buttons, or solenoid valves, translating them into commands that the control system can interpret. Digital modules play a vital role in executing logic operations, controlling actuators, and monitoring the status of equipment within a system.

Importance of Analog & Digital Modules in Industrial Automation

In the realm of industrial automation, analog and digital input output modules offer several key benefits that significantly enhance operational efficiency and system control. Here are some crucial aspects where these modules prove their worth:

Accurate Data Acquisition : Analog modules provide precise measurements of critical variables, enabling real-time monitoring and control for optimal process performance.

High-Speed Response : Digital modules operate at high speeds, facilitating quick decision-making and rapid execution of control commands.

Flexibility & Scalability : Both analog and digital modules offer scalability options, allowing systems to expand and adapt to changing operational requirements seamlessly.

Reliability & Maintenance : These modules are designed for longevity and robustness, ensuring reliable performance even in harsh industrial environments.

By integrating analog and digital input output modules into industrial automation systems, professionals can achieve enhanced control, improved efficiency, and streamlined operations.

Wrapping Up

In conclusion, analog and digital input output modules form the backbone of industrial automation, enabling seamless communication between control systems and field devices. Professionals in the industry must grasp the differences and functionalities of these modules to leverage their capabilities effectively. By harnessing the power of analog and digital input output modules, businesses can elevate their automation processes to new heights of efficiency and productivity.

Next time you encounter these modules in your industrial setting, remember their pivotal role in driving automation forward and optimizing operational performance.

Stay tuned for more insightful articles on industrial automation and emerging technologies!

Comments